UV absorber

When polymer materials are used outdoors, they are degraded by ultraviolet light (UV-light), resulting in yellowing, gloss reducing, embrittlement, cracking, etc. Physical and mechanical properties are also significantly reduced. Therefore, in order to prolong the product life, adding a suitable amount of UV absorber to the plastic or coating product can filter out the harmful UV light and delay the aging of the product. Generally speaking, external absorbers only need to be slightly added (0.2 to 0.5%), which can increase the product lifetime by several times, and at the same time reduce the pollution and resource consumption caused by the aging of the product. This is an environmentally friendly application. According to different chemical structures and applications, UV absorbers are mainly classified into benzotriazoles, benzophenones, and triazines.

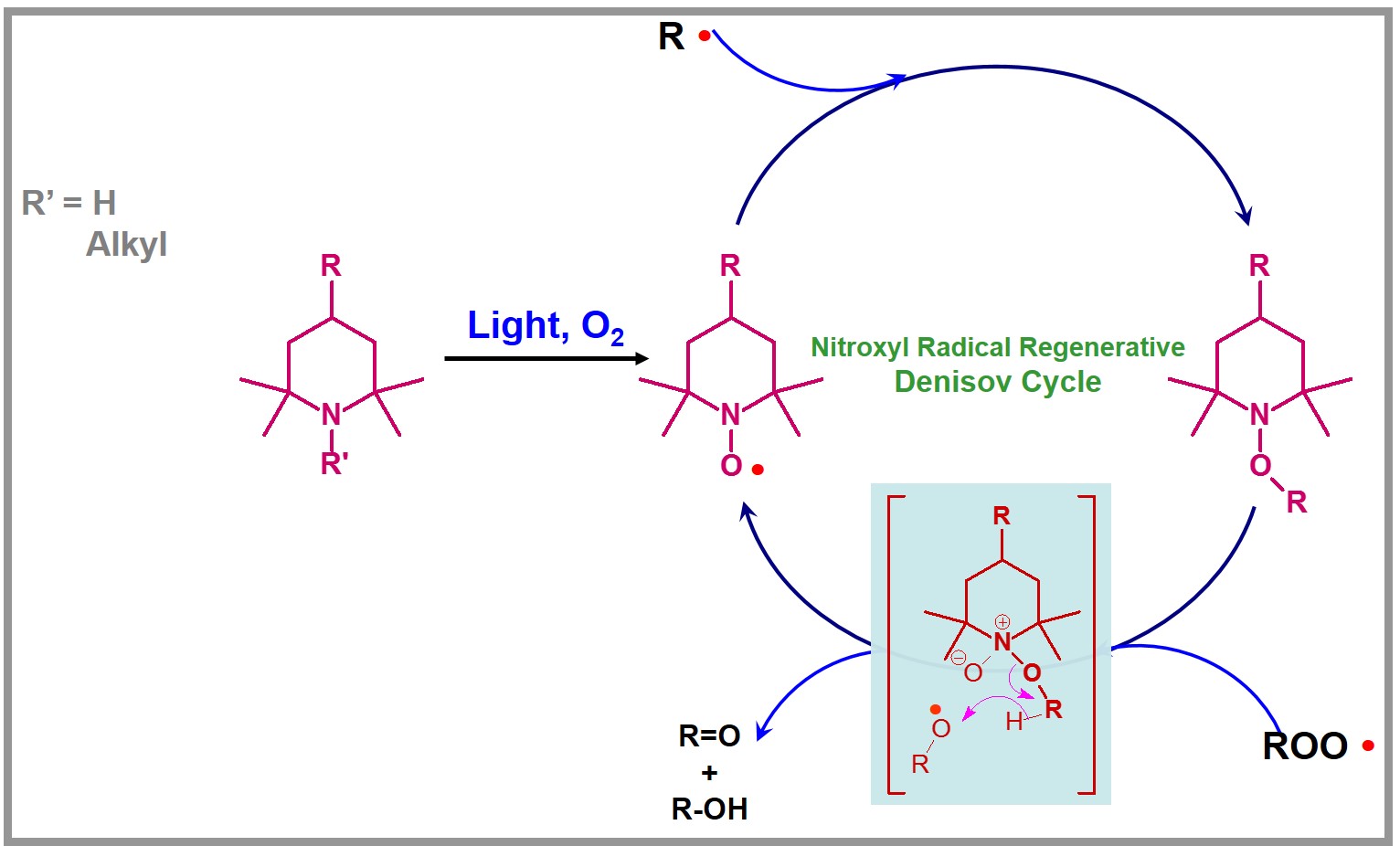

Light stabilizer

Light stabilizers are compounds that repair areas of photooxidation caused by UV light that penetrates into plastics. Its light stabilizer can effectively quench the free radicals caused by photooxidation. Stopping the product to continue to be degraded can be regarded as making up for the deficiency of UV absorbers. Generally, the product generally chooses UV absorbers to be used with light stabilizers. Polymer products more complete protection. Light stabilizers all have a common structure called hindered amines. These products are divided into three main types based on their chemical characteristics: single-molecule, polymeric, and low-alkaline (AR-HALS). When the light stabilizer and the ultraviolet light absorber are used together, a synergistic effect can be achieved.

| CAS No | 6337-43-5 |

| Appearance | White to off-white flake |

| Melting Point | 138-141 °C |

| Loss on Drying | 0.5% max. |

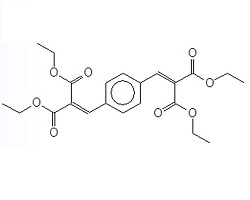

The product is recommended as a highly efficient & colorless UV absorber for plastic materials, particularly engineering plastics such as polycarbonate and polyesters. Eusorb UV-988 which is a benzylidene-bis-malonate type UV absorber with pronounced absorptivity in the high energy (low wavelength) range of the UV spectrum, shows a significant improvement of long term stability of PC. In addition to the stabilization of PC, Eusorb UV-988 also can be advantageously used to improve the light stability of PET to UV light yellowing and brittleness may occur. Eusorb UV-988 would be the good choice of UV absorbers if the maintenance of transparency is required.

| CAS No | 7443-25-6 |

| Appearance | White crystalline powder |

| Melting Point | 55-59 °C |

| Loss on Drying | 0.5% max. |

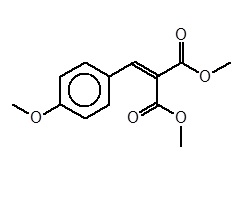

Eusorb UV-1988 is a benzylidene malonate type UV stabilizer which absorbs strongly in the high energy (low wavelength) part of the UV spectrum. Eusorb UV-1988 belongs to the class of UV-B absorbers which protect the stabilized substrates from photodegradation by the matrix screening of UV light.

Addition of Eusorb UV-1988 to plastics does not impair the colour of the stabilized polymers due to specific absorption range of the UV absorber. The strong absorption of Eusorb UV-1988 in the UV-B range assures an effective light stabilization of the plastics. In certain cases, combinations of Eusorb UV-1988 with hindered amine light stabilizers give a further enhancement to the UV protection of polymers.

| CAS No | 18600-59-4 |

| Appearance | White to off-white crystalline powder |

| Melting Point | 310 °C |

| Loss on Drying |

0.5% max. |

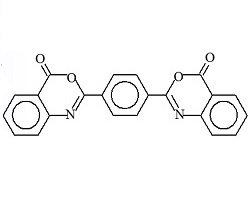

Highly efficient UV absorber for engineering plastics, especially for PET, PBT.

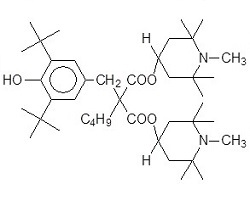

| CAS No | 63843-89-0 |

| Appearance | White to off-white yellow powder |

| Melting Point | 144 °C min. |

| Loss on Drying |

0.5% max. |

Eustab LS-144 is a light stabilizer of the hindered amine class (HALS)and also contains an antioxidant moiety of the sterically hindered phenol type. Its efficiency provides significantly extended life time to coatings by minimizing paint defects such as cracking and loss of gloss. It has tribo gun effect for powder coating to increase powder static adhesion.

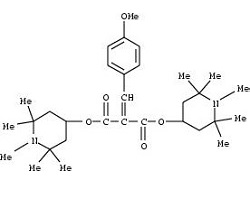

| CAS No | 147783-69-5 |

| Appearance | White to off-white powder |

| Melting Point | 120~125 °C |

| Loss on Drying |

0.5% max. |

Eustab LS-310 is recommended as a light stabilizer for polyolefins, styrene plastics, PVC, PBT. Eustab LS-310 is also recommended in all kind of coatings, air drying and stoving enamels. The concentration should not exceed 1.5% of active stabilizer on solid resins. In clear coats, a combination from Eustab LS-310 and an UV absorber would be recommended.