Anti-Hydrolysis Agent

Polyester-based polymer products hydrolyze easily under acid and water-rich conditions, to generate acid substances after hydrolysis. Acting as a catalyst, the acid substances will further accelerate the hydrolysis reaction, causing cracking or dusting of the polyester-based polymer products. Polyester-based polymers in the hydrolysis process will generate carboxylic acid. Anti-hydrolysis agent brings chemical reaction preferentially with carboxylic acid and water to form a stable compound, which further prevents the degradation from autocatalytic hydrolysis of polymer. The anti-hydrolysis agent is especially suitable for the application under severe conditions such as high temperature, humidity, and acid-base environment. It can enhance the polymer hydrolysis resistance and hydrolysis stability, greatly increasing the reliability as well as prolonging the life of the polymer products. Thus, it can be regarded as a "green additive."

Anti-hydrolysis agent is highly suitable in the following plastic products, which is easily hydrolyzed:

1. Polyester-based polymer products such as PET / PBT / TPEE

2. Polyurethane products such as PU / MDI prepolymer / TPU / adhesive

3. Polyamine (Nylon) products

4. EVA

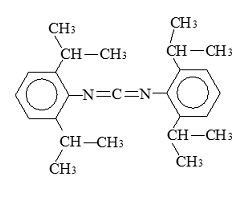

| CAS No | 2162-74-5 |

| Appearance | White to off-white flake |

| Melting Point | 49-53 °C |

| Loss on Drying | 0.5% max. |

Eustab® HS-700F Highly efficient anti-hydrolysis agent for various polymers, in particular for EVA, PA, PET, PBT, PLA, TPEE &, TPU to be protected from premature wear due to hydrolysis. It also acts as a processing auxiliary to prevent a reduction in molecular weight, and may also be used to bring about a deliberate increase in molecular weight.

Eustab® HS-700F acts as an acid and water scavenger and prevents autocatalytic degradation. Eustab® HS-700F is further suitable for stabilization of lubricating greases and oils against water and acid attack.

The recommended quantity for PU systems based on polyester polyols for high-grade TPU products, PU casting elastomers, PU rubber and PU adhesives is between 0.7 to 1.5%. For certain applications, e.g. in EVA, Eustab HS-700F is used between 3.0 to 5.0%.